1. Configuration Options

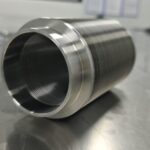

- Custom Fabrication: Supply your technical drawings – we’ll manufacture bellows with precisely matched flanges/tube ends.

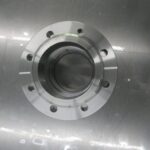

- Standard Flange Selection: Choose from industry-standard UHV flanges (listed below).

- Tube-End Configuration: Direct tube welding ends for piping integration.

- Material Flexibility: 316L SS, Inconel®, Hastelloy®, Titanium, Monel®.

2. Ultra-High Vacuum Flange Standards

| Flange Type | Standard Name | Pressure Rating | Common Applications |

|---|---|---|---|

| CF (ConFlat) | Varian/Agilent Standard | 10−12 mbar range | Semiconductor, particle physics |

| ISO-KF | ISO 2861 (Quick Flange) | 10−9 mbar range | Laboratory vacuum systems |

| ISO-F | ISO 1609 | 10−10 mbar range | High-vacuum industrial systems |

| NW/KF | DIN 28404 | 10−8 mbar range | European vacuum systems |

| ASA/ANSI | ASME B16.5 | Varies by class | Industrial process systems |

| DIN | DIN 2633–2638 | Up to PN40 | European industrial systems |

3. Key Specifications

- Size Range: OD 10–500 mm | ID 10–500 mm

- Pressure Rating: Up to 1000+ psi (material dependent)

- Temperature Range: Cryogenic to 800°C

- End Reinforcement: Optional thickened end convolutions (2–3 layers)

- Leak Rate: < 1×10−10 std cc/sec He (mass spectrometer tested)

4. Manufacturing Process

- TIG/Laser welding of individual diaphragms

- Precision flange/tube-end welding under argon atmosphere

- Helium leak testing of final assembly

- Surface passivation & cleaning for UHV applications

Ordering Options

| Configuration | Required Specifications | Lead Time |

|---|---|---|

| Standard Flange | Flange type, OD/ID, lengths, material | 2–3 weeks |

| Custom Flange | Technical drawings, material spec | 4–6 weeks |

| Tube-End | Tube dimensions, OD/ID, lengths, material | 3–4 weeks |

How to Order

- Select configuration:

- Standard flange (specify type)

- Custom flange (provide drawings)

- Tube-end connection

- Specify dimensions:

- Outer Diameter (10–500 mm)

- Inner Diameter (10–500 mm)

- Free/Compressed/Extended Lengths

- Choose material and end reinforcement option

- Provide quantity requirements

We’ll deliver complete CAD models for approval before manufacturing!

Why Choose Our Flanged Bellows?

- Zero rework: Perfect flange-to-bellows alignment

- UHV-certified welding processes

- Single-source responsibility for entire assembly

- Volume discounts for OEM quantities

- Material certifications for traceability