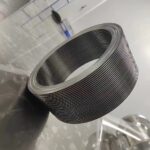

1. Construction & Custom Design

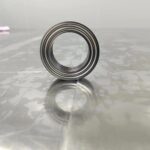

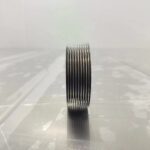

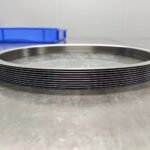

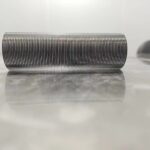

- Made from stamped diaphragms, welded at inner and outer edges via TIG, laser, or plasma welding to ensure hermetic integrity.

- Flangeless format reduces cost and material excess—ideal when you supply your own flanges.

- Optional reinforced end convolutions (outermost two) can be thicker for enhanced weld strength or uniform thickness across all convolutions.

2. Fully Customizable Specifications

Just tell us:

- Outer & Inner Diameter (OD/ID)

- Free Length (unloaded length)

- Compressed Length (fully compressed)

- Extended Length / Stroke

- End Convolution Thickness (reinforced or standard)

We calculate the required convolution count, spring rate, tolerances, and produce precisely to spec.

3. Performance & Capabilities

- Edge-welded design offers outstanding axial, lateral, and angular flexibility—axial stroke up to ~90% of free length.

- Provides hermetic, all-metal sealing with no need for gaskets—ideal for vacuum and high-pressure applications.

- Supports high-cycle fatigue, high/low temperature, and corrosive environments depending on material.

4. Material Options

Choose from a variety of alloys, including:

- Stainless steel (e.g., 316L, 347)

- Nickel alloys (Inconel®, Hastelloy®)

- Titanium, Monel®, AM350

Suitable for cleanroom, vacuum, cryogenic, chemical, and high-temperature environments. Single- or multi-ply

designs available, with optional heat-treatment to enhance performance.

5. Designed for High-Volume Production

- Optimized for repetitive manufacturing—ensuring cost-effectiveness and consistency.

- You handle flange welding in-house; we supply weld-ready components.

- Efficient replenishment workflow as usage grows.

Key Benefits

| Feature | Benefit |

|---|---|

| Flangeless Bellows | Less material wasted, smooth integration into your flange system |

| Reinforced End Convolutions | Easier welding, stronger weld zones |

| Fully Custom Dimensions | OD/ID, free/compressed/extended length tailored to spec |

| All-Metal Hermetic Seal | Leak-tight in vacuum, pressure, or chemical service |

| Flexible Materials & Ply Options | Versatile performance in diverse environments |

| Optimized for Volume Orders | Lower cost per unit, quick turnaround |

How to Order

Just send these details:

- Desired OD and ID

- Free length, compressed length, extended stroke

- End thickness preference (reinforced or standard)

- Material selection (optional—otherwise we’ll recommend based on environment)

We will provide you with:

- Convolution count, spring rate, and dimensional layout

- Estimated lead time and pricing

- A precision-made, weld-ready flangeless bellows built to your specifications

Summary

Our Flangeless Welded Metal Bellows—with optional reinforced ends, full dimensional flexibility,

and industrial-grade materials—deliver precisely what high-volume OEMs and fabricators need when integrating

their own flange assemblies. Share your specs, and we’ll make bespoke bellows for your process.