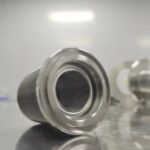

Bellows with Internal Shafts

Design Features:

- Integrated precision-ground shaft running through bellows center

- Hermetic seal between shaft and end plates

- Anti-rotation keyways or splined shafts

- Custom shaft materials: hardened steel, stainless, or ceramic

Benefits:

- Eliminates external linkages

- Maintains alignment in rotary/linear systems

- Transmits torque through sealed environment

- Reduces system footprint

Typical Applications:

- Vacuum rotary feedthroughs

- Hermetic actuators

- Medical device drives

- Semiconductor wafer handling

Extended Length Bellows with Isolation Rings

Design Features:

- Modular construction with intermediate isolation rings

- Ring spacing every 5–15 convolutions

- Rings manufactured from compatible materials (stainless, Inconel)

- Optional cooling channels in rings

Benefits:

- Prevents column buckling in long strokes

- Maintains uniform compression

- Distributes stress evenly

- Allows thermal management

Technical Specifications:

| Max. unsupported length | 2 meters |

|---|---|

| Isolation ring spacing | 50–150 mm |

| Ring thickness | 1–5 mm |

| Max. compression ratio | 40% |

Bellows with Integrated Guide Rods

Design Features:

- Precision guide rods parallel to bellows axis

- Linear bearings integrated into end plates

- Adjustable preload mechanisms

- Corrosion-resistant rod materials

Benefits:

- Eliminates lateral deflection

- Maintains axial alignment

- Prevents torsion during operation

- Increases cycle life by 300%

Configuration Options:

- Single-rod center guide

- Dual-rod opposed configuration

- Quad-rod box guidance system

- Telescoping multi-stage guides

Material & Construction

Bellows Core: 316L, Inconel 718, Hastelloy C-276

Shafts: 17-4PH stainless, titanium

Guide rods: Hard-chromed steel, alumina ceramic

Isolation rings: Matching or dissimilar metals

Welding: EB/TIG welding under argon atmosphere

Finishing: Electropolishing, passivation, UHV cleaning

Custom Design Process

Application Analysis:

- Motion requirements (stroke, speed, cycles)

- Environmental conditions (temp, pressure, media)

- Space constraints and interface points

Engineering Solution:

- FEA analysis for stress distribution

- Buckling calculations for extended lengths

- Wear simulation for guide systems

Prototype Development:

- Functional prototype within 4 weeks

- Validation testing report included

Production:

- Dedicated tooling for custom components

- Lot traceability with material certifications

Technical Advantages

- Precision Alignment: ≤0.05mm runout in guided systems

- Extended Stroke: Up to 1.5m travel with isolation rings

- Load Capacity: Guide rods support up to 500kg axial load

- Vacuum Compatibility: ≤10⁻¹⁰ mbar·L/sec leak rate

- Temperature Range: -270°C to +800°C (material dependent)

How to Order Specialized Bellows

Provide these specifications:

- Primary function (motion transfer, isolation, guidance)

- Dimensional constraints (OD, ID, min/max length)

- Motion parameters (stroke, speed, cycles)

- Environmental conditions

- Special requirements:

- Shaft type (solid/hollow, connection method)

- Guide rod configuration

- Isolation ring spacing

- Surface finish requirements

Lead Times:

- Standard specialized designs: 6–8 weeks

- Fully custom solutions: 8–12 weeks

Volume Production:

- Dedicated production lines for OEM quantities

- Annual volume discounts available

For complex applications, request our engineering consultation service for system-integrated solutions.