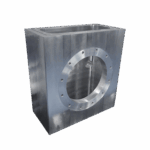

Vacuum Chambers

Our precision-engineered vacuum chambers are designed for demanding applications in ultra-high vacuum (UHV), high-vacuum (HV), and cleanroom environments. Whether used in research, semiconductor processing, or custom vacuum systems, our chambers deliver exceptional performance, leak-tight integrity, and long-term reliability.

Construction & Design

- Material: 304 or 316L stainless steel for excellent corrosion resistance and vacuum compatibility.

- Fabrication: Fully welded construction using TIG welding for hermetic sealing and minimal outgassing.

- Surface Finish: Vacuum-grade internal surface treatment (electropolished or mechanically polished) to reduce virtual leaks and improve pump-down performance.

- Customization: Fully customizable ports (CF, KF, ISO), viewports, feedthroughs, internal brackets, and mounting flanges.

Specifications

- Chamber Shapes: Cubic, cylindrical, spherical, or custom geometries based on your application.

- Wall Thickness: Optimized for structural integrity under vacuum conditions, typically 3–12 mm depending on size and pressure.

- Leak Rate: Helium leak-tested to <1×10-9 mbar·L/s.

- Bakeout Temperature: Compatible with system bakeouts up to 200–250°C depending on material and configuration.

Applications

Used across a range of vacuum technologies including:

- Physical vapor deposition (PVD), sputtering, and thin-film coating systems

- Synchrotron beamlines and particle accelerators

- Space simulation chambers and cryogenic systems

- R&D test chambers in laboratories and universities

How to Order

Please provide the following parameters to receive a quotation:

- Chamber dimensions (length × width × height or diameter × length)

- Required flange types and port configurations (CF, KF, ISO sizes and positions)

- Surface treatment preferences (mechanical polish, electropolish, etc.)

- Operating vacuum level and temperature requirements

- Material selection (304, 316L, custom alloy if needed)

We will provide detailed drawings, pricing, and delivery timeline. All vacuum chambers are helium leak-tested, cleaned for vacuum service, and packaged for cleanroom compatibility.