Edge Welded Bellows: Structure, Design, and Applications

Edge welded bellows are precision-engineered components widely used in industries requiring high-performance sealing solutions. Their unique design ensures leak-proof functionality, durability, and resistance to extreme conditions. Below, we explore their structure, manufacturing process, and key characteristics.

Key Components

Flange (01): Custom-shaped to meet requirements, with preset grooves on the periphery and edge. Welded to bellows, preferably using the same material.

Bellows (02): Formed by stamping metal plates into circular shapes. Thickness and profile vary based on usage conditions.

Pitch (03): Influences pressure resistance, durability, and spring rate.

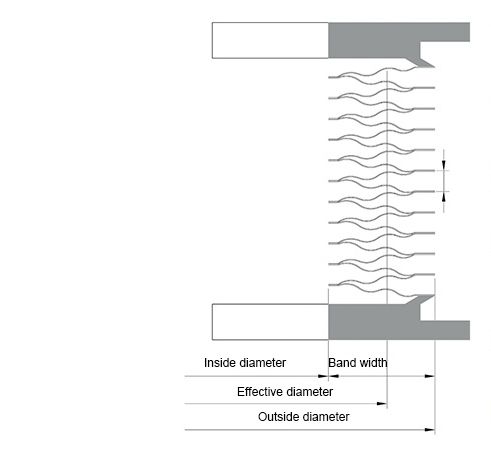

Annule Width (04): Affects flexibility, pressure resistance, and spring rate. Calculated as (OD – ID)/2.

Effective Diameter (05): Defined as (OD + ID)/2.

Outside Diameter (06): Includes labeled dimensions like ID, band width, and effective diameter.

Welding & Testing

Welding Methods:

- Electron Beam (EBW)

- Gas Tungsten Arc Welding (GTAW)

- Laser

- MBPA (PAW MBPA)

- Orbital TIG Arc

Testing Range:

- Life cycles (pressure/temperature indicators)

- Load and mass spectrometer tests (MST)

- Metallurgy and pressure tests (burst/pulse)

Key Characteristics

- Ultra-low leak rate (1×10-11 std. cc He/sec)

- Long lifespan (>1 million cycles)

- High/low temperature resistance

- Low gas output rate

- Corrosion-resistant

Design & Manufacturing

Design Tools: BECAX™ (CAD), FEA, and modeling.

Cleanroom Standards: Expandable to Class 100, 1000, or 10,000.

We produce standard and custom edge welded bellows tailored to specific industrial needs, ensuring precision and reliability.

Categories: Technology

Tags: